Sollum Technologies Review

Dynamic LED Greenhouse Lighting System Results

In this review of Sollum Technologies, we’ll explore the results of growing winter crops in a greenhouse located in the Canadian Pacific Northwest. Using a Dynamic LED grow light system, we evaluated the SUNaaS (Sun as a Service) platform, which integrates quantum light sensors and a computer system to monitor light levels and control individual LED grow lights in the greenhouse. This system was installed in a 12’ x 20’ Gothic arch poly greenhouse operated by Grozine.

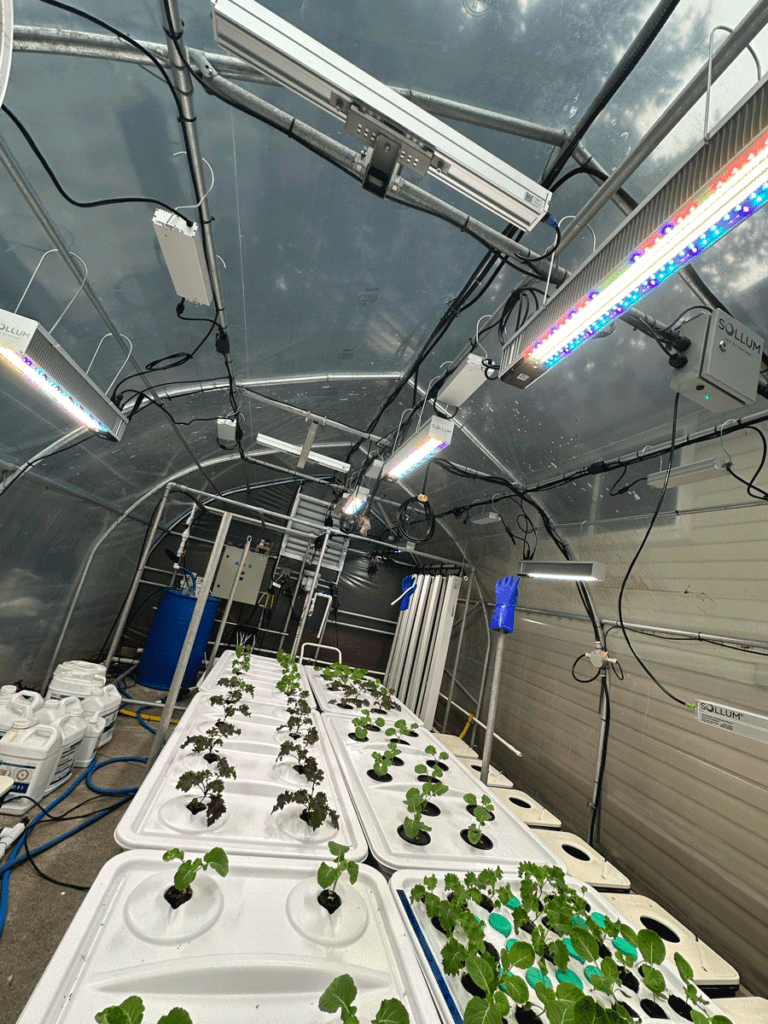

Above: The aeroponic growing system freshly transplanted

Challenges in Winter Greenhouse Cultivation

Winter crop cultivation on Vancouver Island, BC, can be particularly challenging. While temperatures are mild compared to the rest of Canada, the natural light during the winter months is extremely limited in both duration and intensity. In our previous attempts with a basic HPS (high-pressure sodium) lighting system, we saw limited success. While we were able to grow leafy greens using various hydroponic systems, growth was slow, and yields were moderate at best. The high costs of heating and lighting, along with the considerable labor involved, raised doubts about the sustainability of this approach.

Sollum Technologies’ Dynamic LED Lighting System

The SUNaaS platform is a sophisticated and smart lighting service designed for greenhouse cultivation. It consists of several components that work in harmony:

- SF (Sollum Fixture)

- PSU (Power Supply Unit)

- SEC (Sollum Edge Computer)

- SRU (Sollum Router Unit)

- SES (Sollum Ethernet Switch)

- SSR (Sollum Solar Rectifier)

Above: Fixtures, Sensors & Routers communicate to a computer for precise crop lighting

How the SUNaaS Platform Works

At its core, the SSR is a light sensor that measures the incoming natural light in the greenhouse. Several of these sensors are placed throughout the space to monitor changing light levels as the sun moves across the sky. The data gathered by these sensors is then sent to the SEC, the heart of the system, through a network created by the SES and SRU units.

The SEC not only tracks data but also allows the grower to interface with the system. From here, growers can control lighting parameters, adjust settings, and monitor data such as:

- Set photoperiods

- Create lighting zones

- Program target DLI (Daily Light Integral)

- Adjust PPFD (Photosynthetic Photon Flux Density)

- Track power use and set daily power limits

- Control wattage per fixture

- Modify light spectrum for different growth stages

- Access and save lighting recipes

Despite its complexity, the SUNaaS platform is user-friendly, and the system provides a streamlined interface for managing all these functions.

Above: Zone management, easy dynamic grow LED light recipe applications.

Installing the SUNaaS Platform

While the system is advanced, the installation process is straightforward, thanks to the excellent guides and remote support provided by Sollum Technologies. The fixtures and power supply units are lightweight and easy to mount, with various brackets available for different greenhouse structures.

In our experience, installation was quick and painless. With remote assistance from the Sollum team, we easily mapped out the zones and connected the system to the power supply. Using QR codes on each fixture, we quickly assigned serial numbers and configured the system for use.

The team’s expertise, spanning areas like agronomy, IT, and logistics, made the process even smoother. The support staff was exceptionally knowledgeable and provided great customer service, which significantly reduced any technical barriers.

Operating the SUNaaS Platform

Once installed, the SUNaaS platform allowed us to grow crops efficiently, including broccoli, two types of kale, and brussel sprouts using high-pressure aeroponics (HPA).

Above: Quantum light sensors charting natural light patterns in the greenhouse

The system’s ability to manage power consumption was crucial for us, especially given that energy efficiency was a priority for our research. Each fixture uses around 380 watts, and we selected a lighting recipe that delivered a high output, particularly in the red wavelengths, to meet our target 250 µmol/m²/s light intensity. The ability to adjust the light spectrum at any time via the platform gave us great flexibility, enabling us to fine-tune conditions for optimal plant growth.

Thanks to the expert agronomy team at Sollum Technologies, we were able to tailor our setup for each crop’s growth phase. The platform provided detailed data on:

- Daily Target DLI

- Fixture DLI

- Sunlight DLI

- Fixture PPFD

- Sunlight PPFD

This data allowed us to make real-time adjustments and better understand the specific light needs of each crop.

Above: SUNaaS maintaining consistent optimal crop lighting conditions in real time

Success with Dynamic LED Lighting

One of the most valuable lessons we learned from our Sollum Technologies review was how the SUNaaS platform helped us achieve consistent, healthy growth in our crops. For example, broccoli, which had previously failed to develop proper crowns and florets, finally flourished under optimal light conditions. By increasing the DLI (Daily Light Integral) during our light cycles, we were able to see crowns and florets forming throughout the crop.

Previously, it was difficult to monitor and adjust light levels manually, and growers had to rely on guesswork. With the SUNaaS platform, however, we were able to deliver consistent light levels while minimizing energy consumption, thanks to its automated adjustments in real time.

This capability is invaluable, especially for growers using natural sunlight combined with supplemental lighting. As natural light fluctuates, the SUNaaS system automatically ramps the intensity up or down, ensuring that the plants always receive the right amount of light.

Sollum Technologies Review, The Bottom Line

For greenhouse growers, especially those growing in regions with limited natural light during winter months, the Sollum Technologies Dynamic LED Lighting System offers a revolutionary solution. The SUNaaS platform provides precise control over lighting intensity and spectrum, ultimately leading to higher yields, better crop quality, and improved energy efficiency.

In future updates to this review, we will continue to share insights into how the SUNaaS system benefits different crops and how we’re leveraging this technology across the seasons.

Above: Healthy & tight broccoli florets forming in aeroponics

Above: Experimenting with vertical growing lighting applications.

The post Sollum Technologies Review appeared first on GROZINE.