RDWC Systems

Recirculating DWC Hydroponic Systems

RDWC Systems | Erik Biksa |

RDWC systems (recirculating deep water culture) are hydroponic growing systems that are capable of producing outstanding yields, growth rates and harvest quality in a variety of crops in popular cultivation. The basic operating principle of RDWC systems is that they contain a significant depth of nutrient solution per plant or growth module (“bucket”) in a multi-plant configuration. The solution is well aerated and recirculated through all of the modules through piping continuously with a pump. Typically, plants cultivated in RDWC hydroponic systems are bare rooted, with the lids of the modules supporting net baskets or collars that hold the plant firmly in place while allowing bare roots to grow down into the module or bucket below containing the depth of continuously recirculated nutrient solution.

Advantages of RDWC Systems:

-very fast growth rates

-high yield potential

-a homogenous and stable environment for plant roots

-exceptional plant health

-ease of automation

-similar root conditions for each plant in the system

-no over or under watering plants

-the potential to grow medium-less, ie no growing substrate required

-very high Dissolved Oxygen (DO) potential for roots

-crops thrive with lower fertilizer concentrations

-less labor; easy transplanting

-a more hygienic growing environment is attainable

Different Types of RDWC Systems

Besides the different manufacturers and suppliers offering RDWC systems, there are different basic configurations to choose from to best suit your application and cropping style.

Configuration selection will influence things like: overall yield per plant, amount of vegetative growth time required before initiating flowering or fruiting, the overall volume of nutrient solution in the system, and the number of modules required in a given area of square footage.

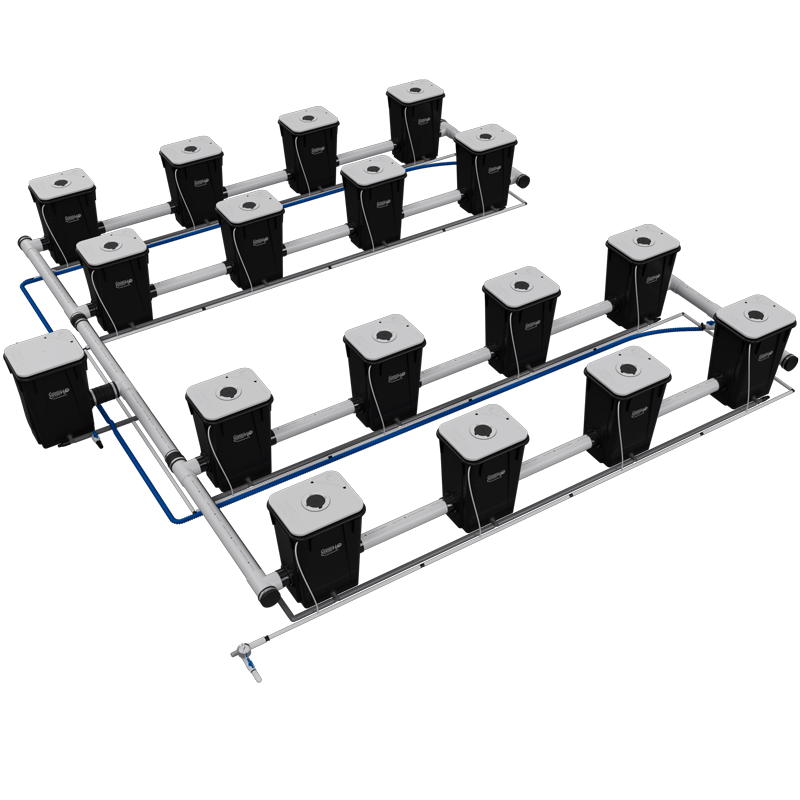

Above: Low Planting Density, High Yield RDWC set up.

Low Planting Density, High Yield RDWC Hydroponics

Individual plants can be grown to very large sizes fairly rapidly with RDWC hydroponics compared to other growing system types. For example to grow plants that finish flowering at several feet tall may only require a few weeks of vegetative growth in a RDWC system before initiating the flowering cycle. This can be especially advantageous for growers who have limits to the number of plants they can manage or produce. Overall cropping time may be comparable to conventional growing methods with higher plant densities. Additionally, plants that finish as very large specimens tend to offer very high yields for the square footage they occupy and can deliver outstanding crop quality. The overall size of flowers and fruits can be quite impressive. Higher ceilings and wider aisle ways between sections for RDWC systems (UC 13 XL & UC 13 XXL) are practical considerations that need to be addressed when setting up for low density, high yield RDWC hydroponics. Additional trellising or cages are typically required for supporting heavy large yielding individual specimens.

Above: High Planting Density RDWC hydroponics configuration with Chiller

High Planting Density, Rapid Crop Turn RDWC Hydroponics

As stated above, early crop development, ie vegetative growth, tends to be very fast in RDWC systems. This means little time is required in vegetative growth before plants achieve an optimal size for flowering or fruiting relative to plant spacing in the system. When planted at higher densities, plants in RDWC systems may only require 3 to 10 days of vegetative growing time to achieve optimal size before initiating the reproductive cycle (flowering or fruiting). For example there may be 6 plants in a two foot by four foot grow module (UC Comm). With only a week of healthy vegetative growth, the entire system will be filled to capacity with biomass by the anticipated date of harvest. Yields can be outstanding, especially given the rapid crop turn rate between transplanting and harvest. Fast crop turns are advantageous in several respects, including the fact that they narrow the window for cropping problems to arise.

High planting density RDWC systems may be adapted to vertical growing multi-tiered installations, given adequate support for systems (each growth module may hold up to 30 US gallons of nutrient solution). The ease of automation, installation and operating reliability make RDWC an attractive option for serious vertical growing operations.

Some examples of configurations:

Why Do Plants Grow so Fast in RDWC Systems?

Because the root environment is easily optimized and remains so consistently. Bare roots are continuously bathed in a well balanced nutrient solution that is rich in Dissolved Oxygen–there is nothing to interrupt or get in the way of plants taking up these vital resources for driving the photosynehetic process. Compare with drip irrigation where the substrate goes from wet to dry. Unused elements begin to accumulate to detrimental levels and plants can experience stresses from both under and overwatering. Additionally common growth substrates may not be able to achieve the dissolved oxygen levels that are consistently available to roots in RDWC systems.

What About Crop Quality in RDWC System Harvests?

RDWC grown plants thrive with lower fertilizer concentrations when compared to other growing methodologies. That’s because the roots are supercharged with higher oxygen levels and don’t have any growth medium to get in the way and tie-up nutrients from fertilizer solutions. This often lends to better tastes and aromas in harvests, ie the plant material produced tastes clean and fresh; not of salty fertilizers.

Do I Need a Chiller for RDWC Systems?

If you are growing with RDWC hydroponics indoors under lights it’s likely that you do because of consistently warm temperatures in the growing area. Optimal nutrient solution temperatures for plant roots, 65 to 72 Deg F, are maintained for increased dissolved oxygen and to avoid any potential problems with root pathogens via hydroponic chillers.

Naturally, there are exceptions, depending on the type of crop and if the nutrient solution can cool off during the dark cycle. Greenhouse growers may be able to operate without a chiller if outdoor temperatures allow for the greenhouse to cool off sufficiently at night.

Additionally, if there is a need for heating the growing environment, the demand can be lessened by using an aquarium type heater to keep the solution in the optimal range. Because plants are 90% water, they will be much warmer than the surrounding air, reducing heating costs for the surrounding environment.

The post RDWC Systems appeared first on GROZINE.